The first step in the manufacturing process of the Madreperla Elements Pearls, is manufacture the core of the pearl. The core is made with a special opaline glass of own production. It’s necessary to have this glass in rods of different diameters, depending of the diameter of the pearl you want to manufacture you’ll use one or another diameter. This glass have two important characteristics: a special founding temperature by fire and the special adhesion, that will guarantee the correct fixation of the diferent covers of colour. This glass is fused by our specialist artisans using fire,and a drop of this glass come down on a metal thread that is rotating. Then this drop of glass became cool and by effect of the rotation the drop became round. Later, this metal thread is eliminated and the core of the perl is subjected to a rigorous quality control.

The next step is coating the pearl with a special enamel of own production that will give to the pearls the characteristic colour and luminosity. The pearl is immersed in this enamel different times to give different coats to the pearl, imitating the process of the pearl oyster. The pearl is subjected another time a quality control.

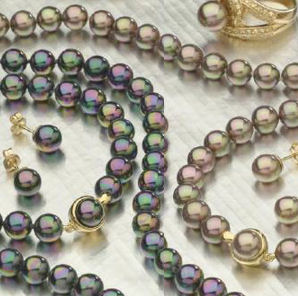

The pearl is now ready. Our artisans guided by an ancient heritage, knots the pearls one by one creating our necklaces and bracelets. Later our pearls are comercialized with a certificate of guarantee, wich ensures the free a replacement of any pearl showing a defect, always that the pearls have been subjected to normal use.

Our soul is bewitched by fire.

The orient of our pearls is deposited and hardened day by day,

imitating the surprising processes of nature.

Able hands, guided by an ancient heritage,

select and create the perfection of our necklaces and jewels.